Horizontal Directional Drilling (HDD) is a construction technique whereby a tunnel is drilled under a waterway or other designated area, and a pipeline or other utility is pulled through the drilled underground tunnel.

The underground tunnel follows an arc line from the entry point, down under the special crossing area, and then resurfaces on the opposite side. Using advanced technology and highly trained technicians, a drill head guides the drilling pipe electronically to ensure the angle, depth, and exit point adhere to carefully designed engineering plans.

(HDD) is a newer technology in pipe and utility installation that allows greater accuracy and flexibility in placement and ends the need for costly digging, large crews, road closures and other complications of traditional digging and pipe installation.

The traditional system of digging down to install pipes and utilities is called “open cut” and is far more disruptive than HDD and comes with many drawbacks. Horizontal directional drilling is likely the best alternative for your repair, maintenance or installation project

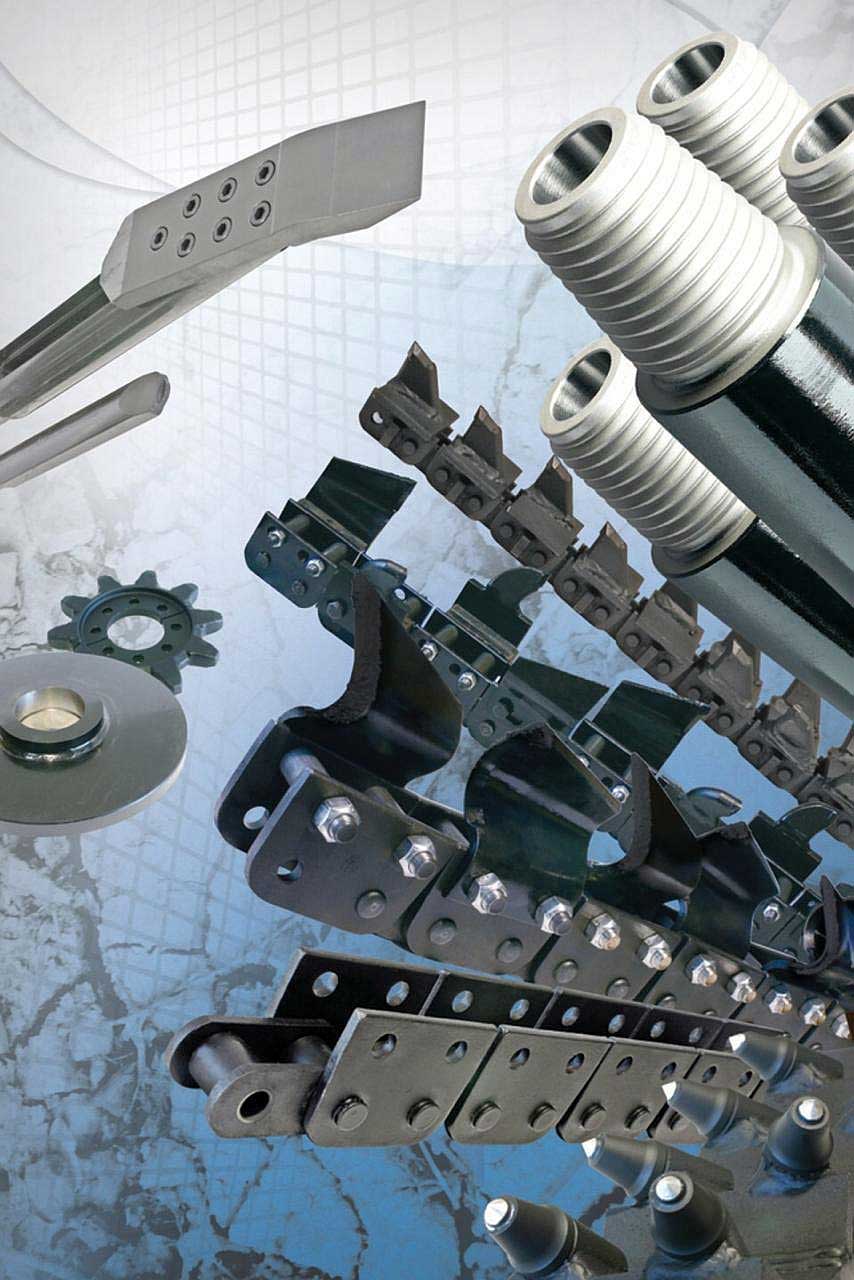

THE TOOLING SELECTION - project , ground conditions . Overlooking any one of these variables can lead to a poor tooling decision.

SELECTING DRILL BITS - Choosing a drill bit that is designed to perform in rock

SELECTING THE HOUSING - will help in promote strong signal strength, consistent steering and ease of operation that match the demands of your plan.

SELECTING BACK REAMING ACCESSORIES - Having the right nozzle placement for the ground conditions can also affect cost of operation.

Copyright © 2024 Drill Tech International DWC LLC

Drill Tech International offers complete drilling systems and solutions for UAE, Bahrain, Qatar, Kuwait, Oman, Jordan, Saudi Arabia, Turkey, Egypt, Angola, Cameroon, Central African Republic, Chad, DR Congo, Republic of the Congo, Equatorial Guinea, Gabon, São Tomé and Príncipe, Rwanda, Burundi.